My friend, The Other Alan, posted photos on Instagram showing how six of his eight roof rack brackets had broken and how he had done a temporary fix with zip ties and bungee cords. He was trying to figure out who the manufacturer had been so he could get new parts.

Since he was about four hours away I suggested he come here so we could make some more effective repairs. ‘Cause we got a shop and tools and stuff.

After studying his photos and getting some measurements from him I picked up a four-foot aluminum bar at the hardware store yesterday.

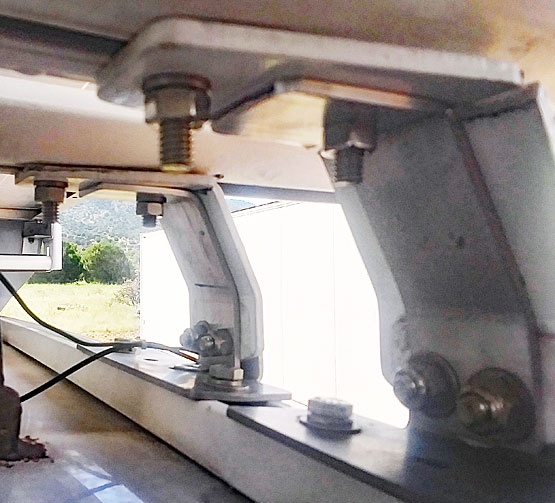

I used one of his unbroken brackets as a guide for where to drill holes as well as where and how much to bend the pieces of bar. I hadn’t done anything like this before, but it seemed within my skill set. I was a little surprised when my first bracket reinforcement gizmo actually fit.

Then I went into mass production mode, cutting five more pieces, stacking them together to drill all the holes at once using the press, then bending them in the vise while clamped next to the master bracket. Not as fancy as shops with 3D scanners, CAD software, plasma or water jet cutters or other high tech stuff. But you can’t beat my no-fee fee.

Start to finish was about three hours, with a 20-minute rain delay in the middle of things. It would’ve been much quicker if I had TIG welding skills and equipment. Sometimes I wish someone had taken me aside in high school and said, “You like creating things, right? Sure, graphic design is one way to go, but if you were to become a welder you could make things out of metal.” Ah, the road not taken.

Pretty impressive, the new bracket reinforcing pieces are really well done.

ReplyDeleteNice work Al!

ReplyDeletelooks weak.I don't think it will hold up.Maybe use steel?

ReplyDeleteWe'll see. No promises were made regarding longevity of the repairs. But it's better than zip ties and bungees.

DeleteThere are so many brackets spaced fairly close together it should hold up just fine. I do this sort of thing for a living ..looking weak and actually being weak don't always add together. If he was hauling a 10 ton crate full of steel anvils driving 80 mph on the surface of the moon then possibly one or two might start failing at a later date. Aluminum can handle much more stress than steel or iron. This was actually one of the reasons stated by Ford when manufacturing the truck beds out of Aluminum.

ReplyDelete